- January 21, 2025

- Abi Therala

- 0

Freight document automation by Wend AI

The logistics industry stands at a technological crossroads, where manual document processing is rapidly becoming obsolete. Following our exploration of automated quote processing systems, we delve into how Wend’s AI-powered solution is transforming the handling of critical shipping documentation.

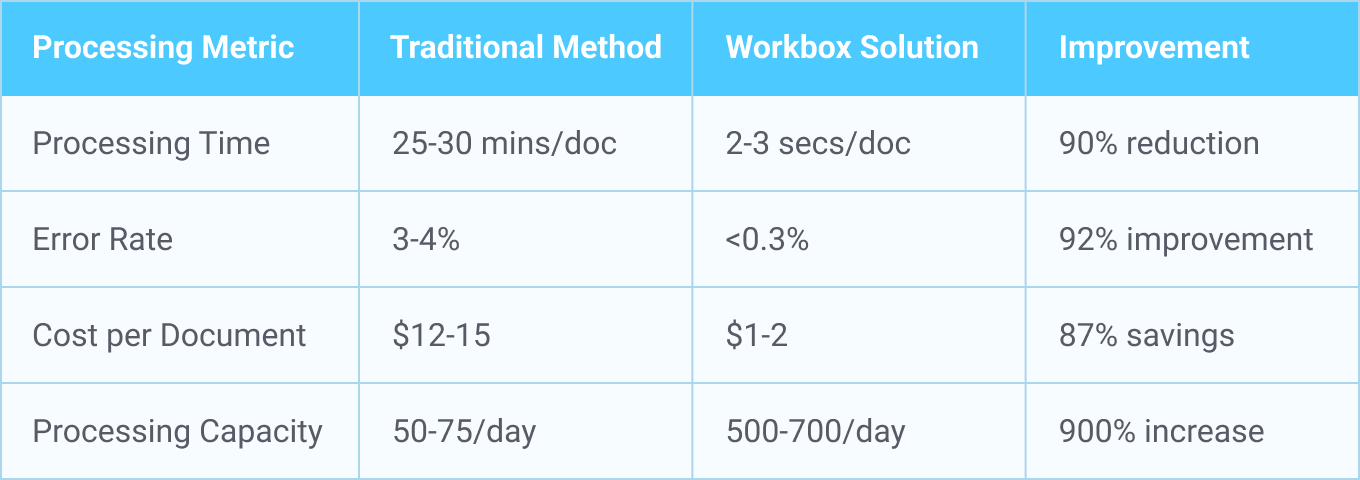

The impact of AI-driven document processing is profound. According to a recent DHL Supply Chain study, companies implementing intelligent document processing solutions reduce manual processing time by 87% while achieving a remarkable 99.7% accuracy rate. The Boston Consulting Group reports that automated document processing can save freight forwarders up to $4.3 million annually in operational costs for every 100,000 documents processed.

From Bills of Lading to Delivery Orders, let’s have a peek at how intelligent automation is reshaping the future of freight documentation.

Understanding Wend AI’s Document Processing Engine

Wend’s AI engine represents a significant advancement in document processing through several key capabilities:

Dynamic Layout Adaptation

The system analyzes document structure in real-time, identifying key information regardless of where it appears on the page. This means it can handle variations in invoice layouts, purchase orders, or shipping manifests without requiring pre-defined templates. For example, whether a purchase order number appears in the header, footer, or body of a document, the system can locate and extract it accurately.

Contextual Understanding

The engine goes beyond simple pattern matching by understanding the relationships between different data elements. For instance, when processing a complex invoice, it can associate line items with their corresponding quantities, prices, and descriptions, even if they’re spread across multiple pages or formatted irregularly. It can also distinguish between similar data types (like different dates on a document) based on their context and purpose.

Continuous Learning System

The engine implements a feedback loop where successfully processed documents contribute to improving the model’s accuracy. When users confirm or correct extracted data, these insights are incorporated into the system’s understanding, making it progressively more accurate for similar documents in the future.

Multi-Format Document Processing: Universal Compatibility

Wend AI’s document handling capabilities seamlessly process diverse document types through an intelligent unified system. Here’s a detailed look at its core capabilities:

Advanced Email Thread Intelligence

Wend AI’s email processing engine excels at handling complex shipping communications. When processing a lengthy email thread about a delayed international shipment, the system automatically extracts and correlates critical information across multiple messages. The engine analyzes entire conversation chains, identifying original delivery dates and their changes, while tracking all modifications throughout the thread. More impressively, it compiles and maintains contextual relationships between tracking numbers, delivery updates, and communication timestamps, ensuring no critical shipping information is lost in lengthy email exchanges.

Smart Multi-Document Correlation

When handling attachments, Wend AI demonstrates remarkable intelligence with format flexibility. Consider a logistics partner sending multiple related documents – a PDF invoice alongside an Excel spreadsheet of line items. The system automatically detects relationships between these different file types, maintaining document hierarchy and version control. It simultaneously extracts invoice numbers and payment terms from PDFs while pulling detailed product quantities and SKUs from spreadsheet tables. During this process, it continuously cross-references information to ensure consistency, immediately flagging any discrepancies between related documents.

Advanced Image Processing

Wend AI excels in handling imperfect real-world documents through sophisticated processing capabilities. At the correction and enhancement level, it automatically adjusts document orientation and enhances image quality for optimal recognition. The system compensates for real-world challenges like shadows, varied lighting conditions, and perspective distortion – particularly useful in warehouse environments where documents might be photographed under less-than-ideal conditions.

Breaking Down Document Processing Capabilities

Bills of Lading (B/L): Beyond Basic Data Extraction

Wend AI transforms B/L processing through:

- Intelligent Field Recognition: Automatically identifies and extracts shipper, consignee, and notify party details regardless of document layout.

- Cargo Detail Processing: Captures package counts, weights, and descriptions while maintaining data relationships.

- Terms & Conditions Analysis: Identifies and extracts special handling instructions and shipping terms.

- Validation Systems: Cross-references extracted data against master databases for accuracy.

Air Waybill (AWB) Automation: Speed Meets Precision

Wend AI’s AWB processing capabilities include:

- IATA Compliance Checking: Automatic validation against current IATA regulations.

- Rate Calculation Verification: Cross-checks declared values against carrier rates.

- Special Handling Code Processing: Identifies and validates handling requirements.

- Route Optimization: Analyzes routing information for efficiency.

Packing List Intelligence: Beyond Line Items

Wend AI revolutionizes packing list processing by leveraging advanced AI to handle complex packaging structures efficiently. Unlike traditional systems that treat packing lists as simple line-item records, Wend AI offers:

- Hierarchical Data Recognition: Automatically identifies nested packaging relationships, such as cartons within pallets or individual items within cartons. This capability ensures precise inventory tracking and customs compliance.

- Unit Conversion: Seamlessly standardizes varying measurement units across documents, such as kilograms to pounds or inches to centimeters. This eliminates errors caused by inconsistent units and simplifies cross-border trade.

- Product Categorization: Uses machine learning to classify items into appropriate categories for customs declarations, ensuring adherence to Harmonized System (HS) codes. This reduces manual intervention and speeds up customs clearance processes.

- Inventory Integration: Updates warehouse management systems (WMS) directly with extracted data, enabling real-time inventory tracking and reducing discrepancies caused by manual data entry.

By combining these features, Wend AI ensures that packing lists become powerful tools for operational efficiency and compliance, reducing time-to-clearance and improving supply chain visibility.

Delivery Order Automation: Last-Mile Excellence

Delivery orders play a pivotal role in last-mile logistics, and Wend AI’s automation ensures seamless coordination between stakeholders. Here’s how:

- Auto-Generation: WendAI can generate delivery orders automatically by extracting and compiling data from shipping manifests, invoices, and other related documents. This eliminates the repetitive task of manual data input.

- Location Validation: Integrated with advanced geolocation services, Wend AI verifies the accuracy of delivery addresses. This feature significantly reduces delivery errors, saving costs associated with rerouting or failed deliveries.

- Dynamic Updates: The system provides real-time tracking of delivery statuses, ensuring stakeholders are informed about the shipment’s progress. Automated notifications can be configured for key milestones, such as dispatch, transit, and delivery.

- Integration Capabilities: Wend AI connects seamlessly with route optimization tools and transportation management systems (TMS). By incorporating dynamic traffic and weather updates, the system enhances route planning for efficient last-mile delivery.

Through these capabilities, Wend AI not only streamlines delivery order management but also improves customer satisfaction by ensuring timely and accurate deliveries.

Advanced Integration Capabilities

Wend AI’s API-driven architecture is a cornerstone of its adaptability and compatibility. It enables the following:

- Seamless ERP Integration: Connects directly with enterprise resource planning (ERP) systems such as SAP, Oracle NetSuite, and Microsoft Dynamics. This ensures synchronized data flow across procurement, accounting, and logistics functions.

- TMS Compatibility: Wend AI integrates with popular transportation management systems, enabling real-time data exchange. This facilitates better load planning, carrier selection, and freight tracking.

- Custom Solutions: The API is designed for flexibility, allowing businesses to create tailored workflows. For example, a freight forwarder can use Wend AI to integrate with port authority databases for streamlined customs clearance.

- Future-Ready Scalability: Wend AI’s modular architecture supports the addition of new capabilities as business needs evolve, ensuring it remains a future-proof investment.

By offering these robust integration options, Wend AI positions itself as a comprehensive solution that adapts to the unique needs of the logistics industry. For industry standards and best practices, visit the Digital Container Shipping Association.

Security and Compliance

Wend AI maintains the highest security standards, as outlined by the International Federation of Freight Forwarders Associations:

- End-to-End Encryption: Employs advanced encryption protocols to protect sensitive data during transmission and storage, safeguarding against unauthorized access or breaches.

- Role-Based Access Control: Restricts access to critical information based on user roles, minimizing the risk of internal misuse or accidental disclosure.

- Audit Trail Maintenance: Keeps a detailed log of all system interactions, which is invaluable for compliance audits and internal reviews.

- Regulatory Compliance: Aligns with global data protection laws, including GDPR, HIPAA, and CCPA. This ensures that businesses operating internationally can confidently use the platform without fear of non-compliance penalties.

These measures not only enhance operational trust but also provide a competitive edge by aligning with the digitalization goals of leading freight companies.

FAQs

1. How accurate is Wend AI’s document processing compared to manual data entry?

Wend’s advanced AI models consistently achieve accuracy rates exceeding 98% across diverse document types, significantly outperforming manual data entry which typically has error rates of 1-4%. Independent testing has shown that Wend AI reduces processing errors by up to 90% compared to traditional manual entry methods, particularly excelling in complex documents with multiple data fields. The system also flags uncertain extractions for human review, ensuring critical data is never misprocessed.

2. What sets Wend AI apart from template-based solutions?

Unlike template-based systems, Wend AI uses advanced AI that adapts to different document layouts automatically. It doesn’t require pre-defined templates or rules, making it more flexible and efficient than traditional solutions.

3. How does Wend AI maintain accuracy with poor-quality documents?

Wend AI employs multiple processing layers, including advanced image preprocessing and AI-based content recognition. This multi-layered approach ensures high accuracy even with suboptimal document quality.

4. Can Wend AI handle custom document types?

Yes, Wend’s AI engine learns from each new document type it encounters. The system can adapt to custom formats without requiring manual template creation or extensive configuration.

5. What kind of implementation support does Wend AI provide?

Wend AI offers comprehensive implementation support, including system integration assistance, custom configuration services, and ongoing technical support to ensure optimal performance.